Small Roti (Chapati) Machine RCA-03 800 To 1000 (P/Hr.)

Small Roti (Chapati) Machine RCA-03 800 To 1000 (P/Hr.)

Introduction of The Roti (Chapati) Machine – In summary, Overall, the Small Roti (Chapati) Machine RCA-03 is a valuable tool for businesses that require a large quantity of chapatis on a regular basis. It streamlines the production process, saves time and labor, and helps maintain consistent quality in the chapatis produced.

₹180,000.00 Original price was: ₹180,000.00.₹170,000.00Current price is: ₹170,000.00.

Additional information

| Model No. | RCA-03 |

|---|---|

| Motor | V-Guard/ Any Standard Make |

| Warranty | 1 Year |

| Power Supply | 220-230 V (Single Phase) |

| Material | Stainless Steel |

| Heigh | 5" |

| Motor Power | 4 H.P. |

| Coating Plat | Ceramic |

| Feature | Corrosion Resistance |

| Roti Baking | Three Layer Technology |

| Gas Connection | LPG-PNG |

| Gas Consumption | 1.2 To 1.75 KG/ Hr. |

| Thickness of Chapati | 2 mm |

| Thickness Adjustable | 1.2 mm to 5 mm |

| Contact Parts | Stainless Steel 304 |

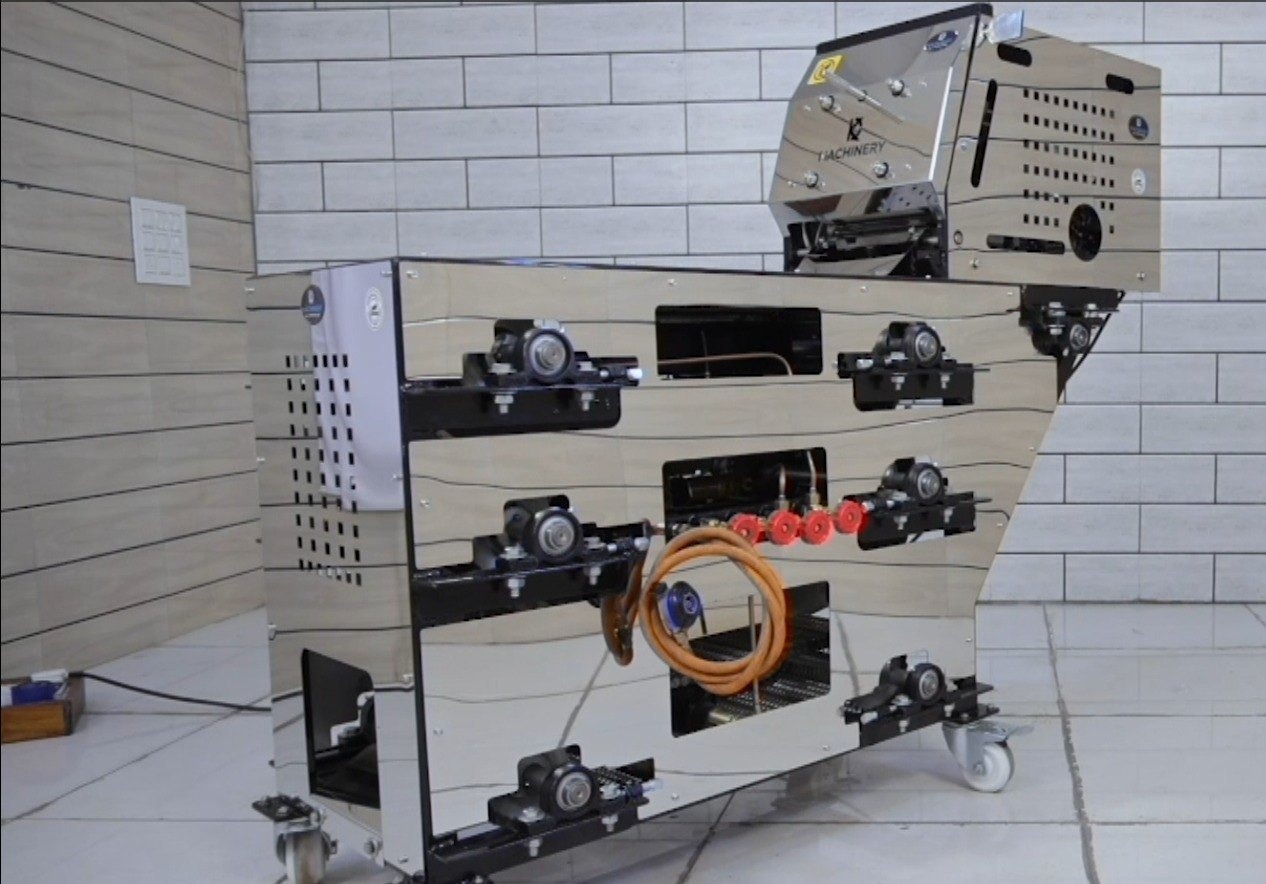

| Design Type | Conveyor Type |

| Gear Box | Standard Make |

| Bearing | Standard Make |

| Automation Grade | Automatic |

| Body Cover | Stainless Steel 202 |

| Color | Silver |

| Capacity | 800 To 1000 (P/Hr.) |

| Size | 65" X 23" X 54" (L*W*H) |

| Weight | 300 KG |

| Usage/ Application | Hotel/ Restaurant |

| Place | Made in India |

Product Description

Introduction of The Roti Chapati Machine – The Small Roti (Chapati) Machine RCA-03 is a piece of equipment designed for making rotis or chapatis in a commercial or industrial setting. It is capable of producing a high volume of chapatis per hour, specifically in the range of 800 to 1000 chapatis per hour. This makes it a valuable addition to restaurants, catering businesses, and food production facilities where a large quantity of chapatis is required to meet customer demand.

Key features of the Small Roti (Chapati) Machine RCA-03 may include:

- Automated Operation: The machine is designed to automate the process of rolling out dough and cooking chapatis, reducing the need for manual labor.

- High Production Capacity: With the ability to produce 800 to 1000 chapatis per hour, this machine significantly increases the efficiency of chapati production compared to traditional methods.

- Adjustable Thickness and Size: Some models allow for customization of chapati thickness and size, ensuring that the chapatis meet specific requirements.

- Consistency: The machine can produce uniform and consistent chapatis, which is crucial for quality control in a commercial kitchen.

- Easy Maintenance: Many of these machines are designed for easy cleaning and maintenance, which is essential for their continuous operation.

- Stainless Steel Construction: Many models are constructed from stainless steel, making them durable and suitable for commercial use.

- Energy Efficiency: Some machines are designed to be energy-efficient, helping to reduce operating costs.

- Safety Features: Safety features such as emergency stop buttons and safety guards may be included to ensure the safety of operators.